Pothole Patchers

OPERATORS LOVE OUR MACHINES. RESIDENTS LOVE THE RESULTS.

DEAL WITH FEWER POTHOLE COMPLAINTS—ALL AROUND

Because our equipment patches potholes better, faster, and with longer-lasting results, chances are you will get fewer constituent complaints.

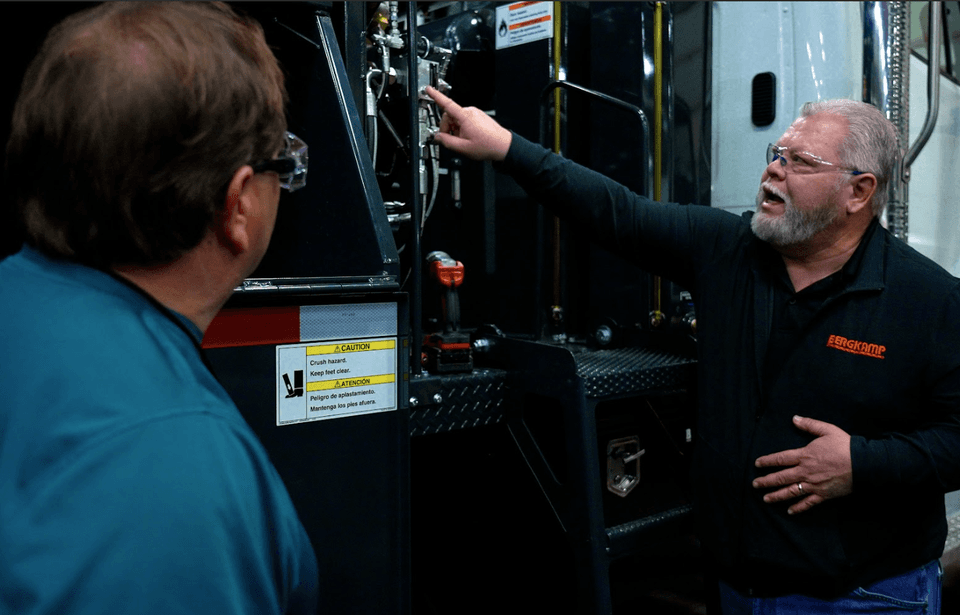

Operators love us because our machines are safer and reduce physical strain. Mechanics love how easy our machines are to service. And fleet managers love how reliable our equipment is, and the lower cost of ownership. So, no complaints from them either.

OPERATOR-CENTRIC DESIGN

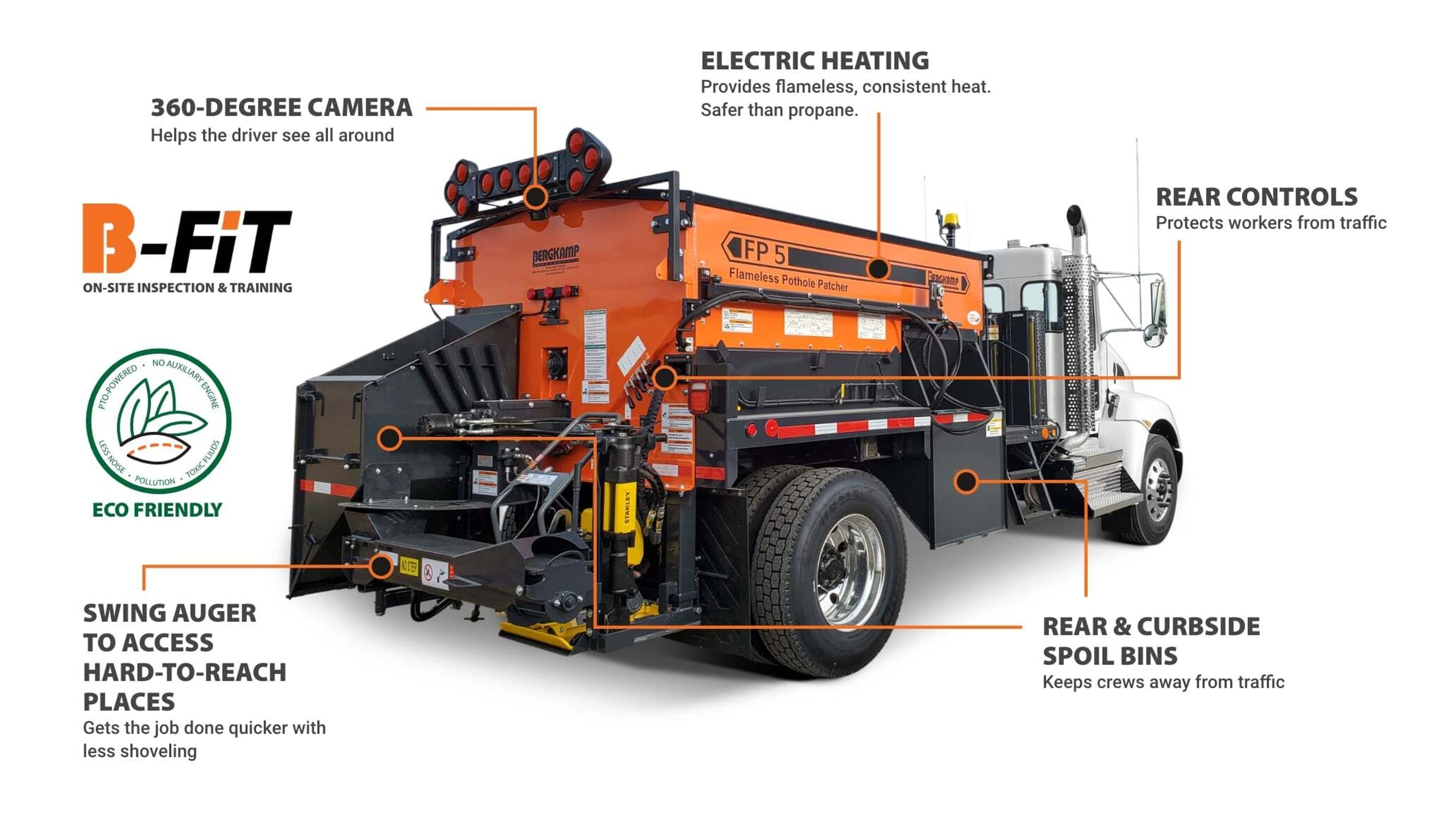

Our equipment is designed with the operator in mind. All the tools for the job are placed exactly where they need to be while eliminating heavy lifting. That means greater efficiency, safety and less strain. Our machines are equipped with lights, cameras, failsafes, and alarms to protect workers.

THE GREENEST POTHOLE PATCHERS ON EARTH

Electric heating greatly reduces greenhouse gas emissions. Our FP5 Pothole Patcher uses a flameless, electric heater to keep the material at a consistent temperature for working and non-working hours. The SP5E Pothole Patcher has no auxiliary engine so there are even fewer emissions.

THE SAFEST WAY TO PATCH

All aspects of our patchers are designed to ensure worker and public safety and keep crews out of oncoming traffic. The SP5E’s remote controlled spray arm means the operator never leaves the cab. And the FP5 uses an electric heated hopper which is much safer than a flame-heated tank burning diesel, propane or oil.

SEE OUR MACHINES

ELECTRIC POTHOLE PATCHER

BERGKAMP FP5

The greenest patcher on the market, designed with the operator in mind. It’s the patcher crews prefer.

FP5 MEDIA GALLERY

SPRAY INJECTION POTHOLE PATCHER

BERGKAMP SP5E

The safest and easiest way to patch. A single operator can patch 100 potholes a day without leaving the cab.

SP5E MEDIA GALLERY